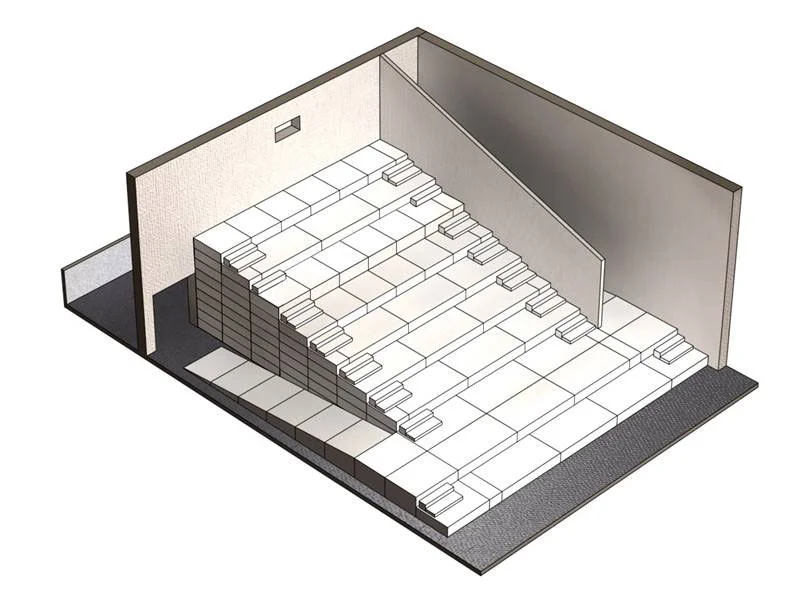

The most economical, time-saving and flexible solution for permanent tiered seating platform construction — Go from clean slab to finished tiered seating platforms in days, not months.

PREFOAM™ DRY-FIT riser system by SSE, is engineered to meet the requirements of virtually any project requiring tiered stadium seating including:

•New construction of stadium riser platforms

•Converting the current sloped floor into stadium risers

•Overstepping of existing risers

•Virtually any shape or configuration in any height or depth

PRERFOAM™ DRY-FIT riser system utilises EPS Geofoam blocks for the structural support, and is based on a proprietary design for a plywood or cement board facing materials. The prefabricated system is easily and quickly assembled and installed, without having to introduce a wet trade (e.g. concrete) into the auditorium, which saves valuable time and money, and enhances the on-site productivity.

EPS Geofoam blocks have very low density, good insulation, low hydraulic conductivity, as well as strength and deformation properties that complement soil behaviour (e.g. retaining structure for slope stabilisation). The primary materials can be locally sourced out, through SSE’s regional manufacturing partners throughout the world, providing further cost and time efficiencies.

PREFOAM™ DRY-FIT riser system is 100% recyclable and made with a minimum of 10% post-consumed material.